Application of extruded polystyrene foam XPS

Lastly, it was established that the external walls, with proper thermal insulation, are the main source of heat loss. Through them you can “vivaporate” up to 45% of the heat. Therefore, the insulation of garden structures must be given special attention. In this case, thermal insulation work is possible both when constructing new structures and when repairing existing ones.

In order to eliminate significant heat losses from the very beginning of the operation of the facility, thermal insulation robots operate in the process of working with empty walls. The optimal heat-insulating material for this is extruded polystyrene. It has little resistance to deformation, has low heat, water and vapor permeability, does not age, does not rot and has a very long service life. Everything is important, since with such a design of the walls, repair robots are practically impossible. In the process of thermal insulation of empty walls, thermal insulation slabs made of extruded polystyrene foam are fastened to a non-extruded wall with an adhesive sheath and dowels. Behind the leveling plaster ball, the dry-decorative masonry is covered with sand and the leveling gap is filled with sand.

Once in use, it will be necessary to frequently coat the walls in the middle with additional thermal insulation. This option is suitable if it is possible to install external thermal insulation or if there is a need to preserve the original faade. Plates made from extruded polystyrene foam, when combined with other heat-insulating materials, are the most practical. Given the simplicity of their installation and the ease of eliminating stench, it is significant to outperform analogues in terms of physical characteristics and at the same time they are environmentally friendly, which is important in closed areas. A variety of slabs made from extruded polystyrene foam for this type of work has a rougher surface to ensure a good adhesion to the heating materials.

The installation of thermal insulation boards made of extruded polystyrene for external use is possible both for new buildings and for reconstruction of buildings. This will ensure a high level of energy saving and expand the possibilities for faade modeling.

Recommendations for insulating walls with polystyrene foam boards:

1. Glue the slabs of extruded polystyrene foam from the bottom, laying the slabs horizontally in one row.

2. Work must be carried out at a temperature not lower than +5 °C, in dry weather.

3. The next row of slabs is inserted into the stick before the bottom row is already glued. It is not allowed to re-install the glued slabs, as well as change the position of the slab along the completed sections after gluing.

4. In cases of low, unstructured walls (old plaster peels or collapses with weak hammer blows), slabs made of extruded polystyrene foam are fastened sufficiently mechanically using additional dowels. The maximum amount of dowels found in buried walls is the same: for walls under plaster - 6 cm, for walls with hollow ceramic tiles and lightweight concrete - 9 cm. The quantity of available elements should be 4-6 pcs/m2, on heap plots 8 pcs/m2.

5. The reinforcing mesh is applied after 3 days of gluing the expanded polystyrene (this will ensure the protection of the expanded polystyrene from direct injection of polystyrene). Apply the glue with a 3 mm thick ball, starting from where you are. The mesh is applied to the fresh ball of glue, leaving 15 cm of mesh behind the horn, which then needs to be folded and pressed on the other side of the net. The overlap of the sieve mesh is liable to become 10 div.

6. The sections of thermal insulation boards at the window openings are covered with mesh measuring 20x35 div. The rolls in front of the mesh overlays must be protected from damage with aluminum rolls.

7. The vial plaster ball must be applied no earlier than 3 days after applying the mesh. Work must be carried out at temperatures ranging from 5 °C to 25 °C in clear and windless weather. The top ball of plaster is applied using what is called the “wet on wet” method, which means that laying is carried out if the lower ball has not yet collapsed.

8. The amount of vicorized insulation should be satisfied as laid down in the project.

![]()

- ←Previous news The most modern insulation

- Next news→ Insulation of walls from the internal side

Polyurethane skirting Orac Decor SX137

Polyurethane skirting Orac Decor SX137 Cornice flexible profile

Cornice flexible profile Photo curtains

Photo curtains Liquid wallpaper

Liquid wallpaper Primehouse ready-made roller blinds

Primehouse ready-made roller blinds Photo wallpaper

Photo wallpaper Decorative fireplace Harmony FP1103

Decorative fireplace Harmony FP1103 Children's

Children's Moldings

Moldings Isoplaat underlay quiet running 5 mm

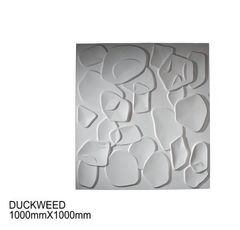

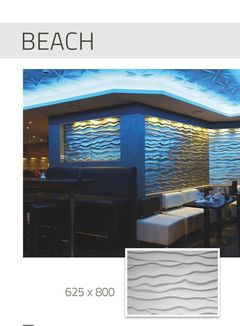

Isoplaat underlay quiet running 5 mm 3D WallArt Tetris panel

3D WallArt Tetris panel Window sill Danke

Window sill Danke Ulf Moritz inserts and elements

Ulf Moritz inserts and elements Decorative beams

Decorative beams Ceiling decor

Ceiling decor